- Top Results

- Bosch Sensortec Community

- Discuss

- MEMS sensors forum

- Re: BME688 for Embedded Design - Starter

BME688 for Embedded Design - Starter

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

BME688 for Embedded Design - Starter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

04-11-2023 09:09 AM

Hi There,

We are serious to consider using BME688 for developing a commercial product. I have tried to find an BME688 application note that a typical component would normally come together with datasheet but could not find one. Can anyone help me with the answers to the following questions (it will be much helpful to include the information in an application note or design guide):

1. Hardware and mechanical enclosure design guides to get the best performance of and the most needed gas around BME688 for needed performance and accuracy. For example, if a closed enclosure has one inlet open and no ventilation, will the BME688 do not get enough gas to perform measurement?

2. What are the minimum horse power and memory requirements of a mcu to connect to BME688 and perform the data processing to obtain the results?

3. What are the standard gas test equipment or test houses needed to verify and validate the output of BME688?

4. Since BME688 datasheet claims the capabilties to measure H2S, CO2, CO1, humility concentration levels, is there any mature configuration data and libraries we can just directly use to build our application instead of purchasing the development kit to re-do the experiment to build the configuration and calibration data?

5. BME688 datasheet also claims the feature of detecting diaper state, is there a configuration and library and application program available for us to try and test?

6. For industry application of BME688, is there an application example avaible for us to follow?

7. Has anyone use BME688 to build a proved medical device? Application example(s)?

It would be greatly appreciated if you could answer or shed some light to the above question.

Rick

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

04-11-2023 11:00 AM

Hi rlin788,

1. For BME688 hardware and mechanical enclosure design guides, you could refer HSMI(Handling, Soldering and Mounting Instructions) document https://www.bosch-sensortec.com/media/boschsensortec/downloads/handling_soldering_mounting_instructi...

Ensure that the BME688 has normal airflow in structure design, not enclosed.

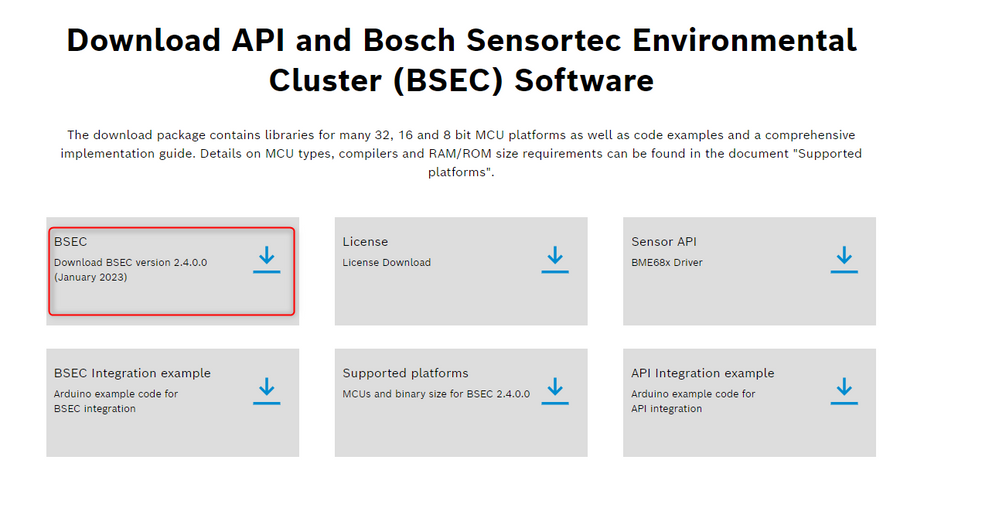

2. There is memory requirement file under BSEC library package.

If you download latest BSEC package from https://www.bosch-sensortec.com/software-tools/software/bme688-software, you will find memory requirement in package.

For example the memory requirement for AVR 8 bit MCU is like this:

BSEC2.4.0.0_Generic_Release_23012023\algo\normal_version\bin\avr\AVR8_megaAVR\libalgobsec.a.Size.log

text data bss dec hex filename

58608 0 3664 62272 f340 (TOTALS)

3,4,5,6,7: typically, users build a lab environment based on actual projects and get an experienced configuration that meets the requirement of product. Currently there is examples of HandSanitizer based on dev kit: https://github.com/boschsensortec/Bosch-BSEC2-Library/blob/master/examples/generic_examples/basic_co...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

04-12-2023 04:08 AM

Thank you for the prompt response! It is helpful.

Is it possible to use a single BME688 to quantitatively measure Radon, H2S, CO2, CO1 to the ppm or ppb level? What are the steps to do it?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

04-13-2023 04:12 AM

The BME688 spec in your website states that "The gas sensor can detect Volatile Organic Compounds (VOCs), volatile sulfur compounds (VSCs) and other gases such as carbon monoxide and hydrogen in the part per billion (ppb) range" and "Major direct outputs: Index for Air Quality (IAQ), bVOC-& CO₂-equivalents (ppm), Gas scan result (%) & many more (all listed in datasheet in Table 20: BSEC outputs)". Therefore, there should be work done already to support the statement. Can you please share the info and examples? Or it would also be appreciated if you would provide the process and steps to achieve:

1. obtaining the value of carbon monoxide and hydrogen in the part per billion (ppb) range.

2. obtaining the value of CO₂-equivalents (ppm).

Thanks in advance!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

05-05-2023 08:57 AM

Hi rlin788,

BME68x is a metal-oxide based chemical sensor. The sensor output is created by interaction of volatile organic compounds (VOCs) with the sensitive layer of BME680. Unlike a physical sensor (e.g. pressure sensor like BMP), chemical sensors are thus influenced by a plethora of parameters and their response is very complex. On the one hand, this implies that quantification of VOCs is not possible in a random VOC mixture like the one the sensor faces in a real world environment.

Still looking for something?

- Top Results